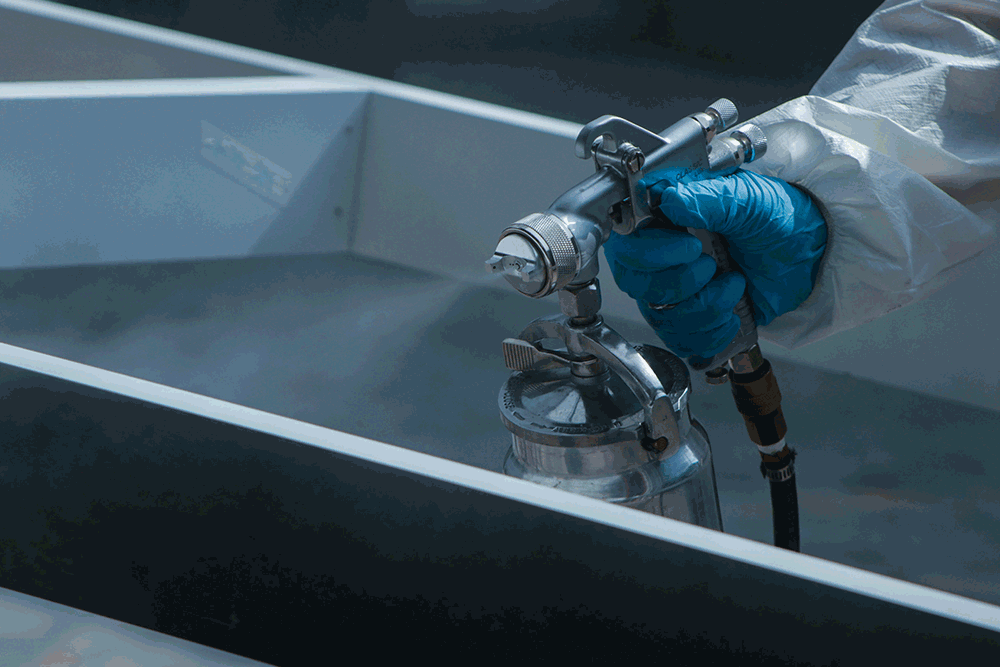

Services of the Steel Industry

Traditional coatings offer temporary relief from wear and corrosion. So, our question is: Why choose a traditional coating when you can have an advanced one?

Read More

Services Based for The Power Industry

In the demanding world of power generation, maximising equipment lifespan and minimising downtime are the need of the hour. Boiler tubes, chimneys, and other structural components in power plants face intense environmental pressures, which often lead to costly shutdowns and frequent maintenance.

Read More

Services of the Power Industry

In the power industry, equipment durability and efficiency are the most important factors. Frequent maintenance or breakdowns due to wear and corrosion can lead to costly, unplanned shutdowns.

Read More

Analysis of Thermal Spray Coating Market

The thermal spray coating industry is growing steadily, with an estimated market size of USD 10.46 billion in 2023, projected to expand at a rate of 4.8% annually until 2030.

Read More

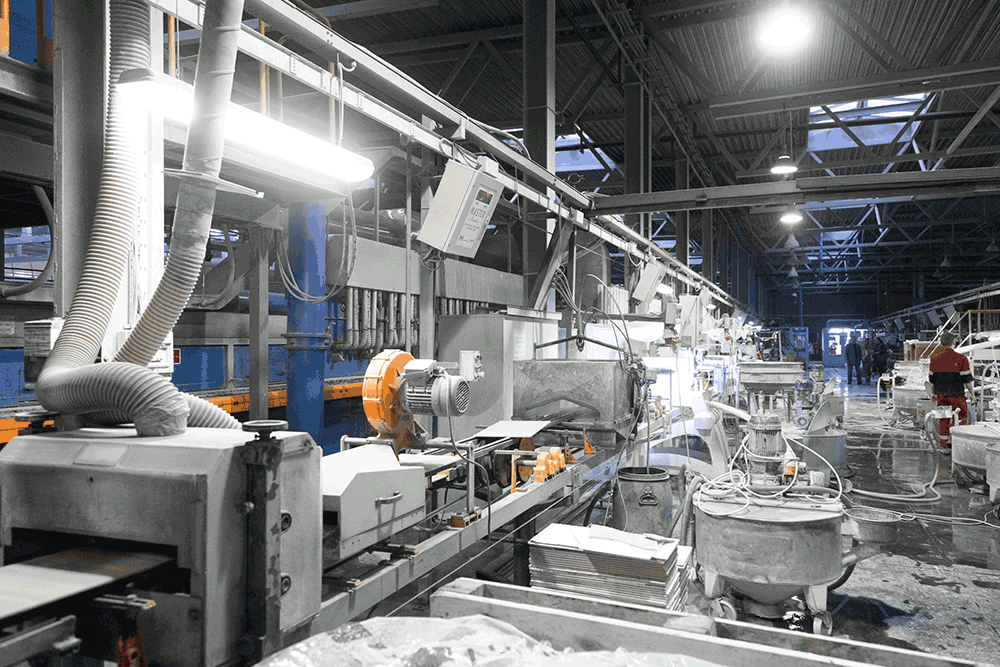

Services of Cement Industry

In the cement industry, maintaining equipment reliability and minimising downtime are important for performance.

Services-based post for the paper and pulp industry: List down all our services and why one should choose us.

Why settle for ordinary when you can have extraordinary?

In today's competitive market, businesses cannot afford to compromise on quality.

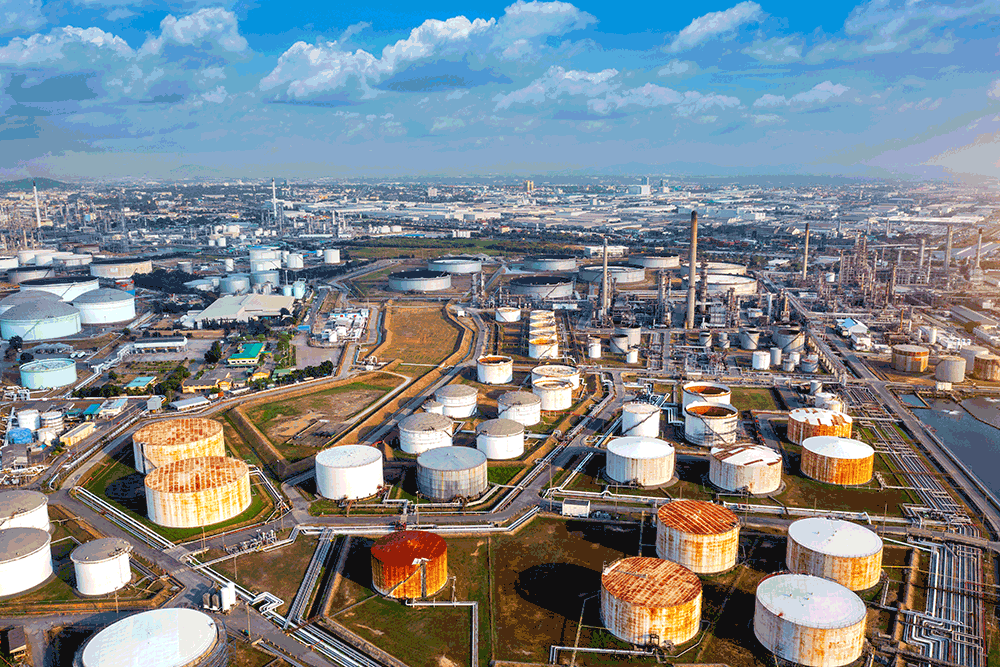

Services of oil and gas refinery

Oil and gas refineries face some of the harshest working conditions, where corrosion can cause damage to important equipment. Prolonged exposure to chemicals, high temperatures, and moisture accelerates wear and tear, leading to costly downtime and repairs.

Read More

How to choose the right coating for corrosion protection

Discover the best coatings for corrosion protection in the chemical industry. Learn about barrier coatings, sacrificial coatings, and expert solutions to extend equipment lifespan and reduce maintenance costs.

Read More

HVOF Coating: Benefits, Process, and Industrial Applications

HVOF (High-Velocity Oxy-Fuel) coating is a thermal spray technique designed to enhance wear resistance, prevent corrosion, and improve thermal stability in industrial components. Used in aerospace, automotive, and energy sectors, HVOF coatings extend the lifespan of machinery and improve operational efficiency.

Read More

Coating Solutions for Chemical & Fertiliser Industry

The chemical and fertiliser industries face challenges like corrosion, wear, and chemical damage, leading to equipment failure and high maintenance costs. Metatech provides advanced coating solutions to protect critical infrastructure, enhance durability, and reduce downtime.

Read More

How Thermal Spray Coating Enhances Durability Efficiency

In today's demanding industrial world, equipment constantly faces wear, corrosion, and extreme temperatures. Thermal spray coating provides a protective shield that extends component life and boosts efficiency. Learn how Metatech’s advanced coatings help industries reduce maintenance costs and downtime.

Read More

Role of HVOF Coating in Aerospace

High-Velocity Oxy-Fuel (HVOF) coatings protect aerospace components like turbine blades, landing gear, and engine parts from wear, corrosion, and heat damage. These coatings improve performance, durability, and reduce maintenance needs, making them essential for modern aviation.

Read More

Role of HVOF Coating in Automotive

High-Velocity Oxy-Fuel (HVOF) coatings are vital for automotive components, providing superior wear resistance, corrosion protection, and thermal durability. They help critical parts like engine valves, suspension systems, and brake rotors last longer and perform efficiently.

Read More

Role of HVOF Coating in Oil and Gas

High-Velocity Oxy-Fuel (HVOF) coatings improve the performance of oil and gas equipment by providing protection against wear, corrosion, and extreme temperatures. These coatings help increase the durability and reliability of components such as drill bits, pipelines, and valves.

Read More

Role of HVOF Coating in Mining

High-Velocity Oxy-Fuel (HVOF) coatings increase the durability and efficiency of mining equipment by providing protection against wear, corrosion, and impact. These coatings help critical components such as drill bits, crushers, and conveyor systems operate reliably in harsh environments.

Read More