Services Of Oil And Gas Refinery

INTRODUCTION

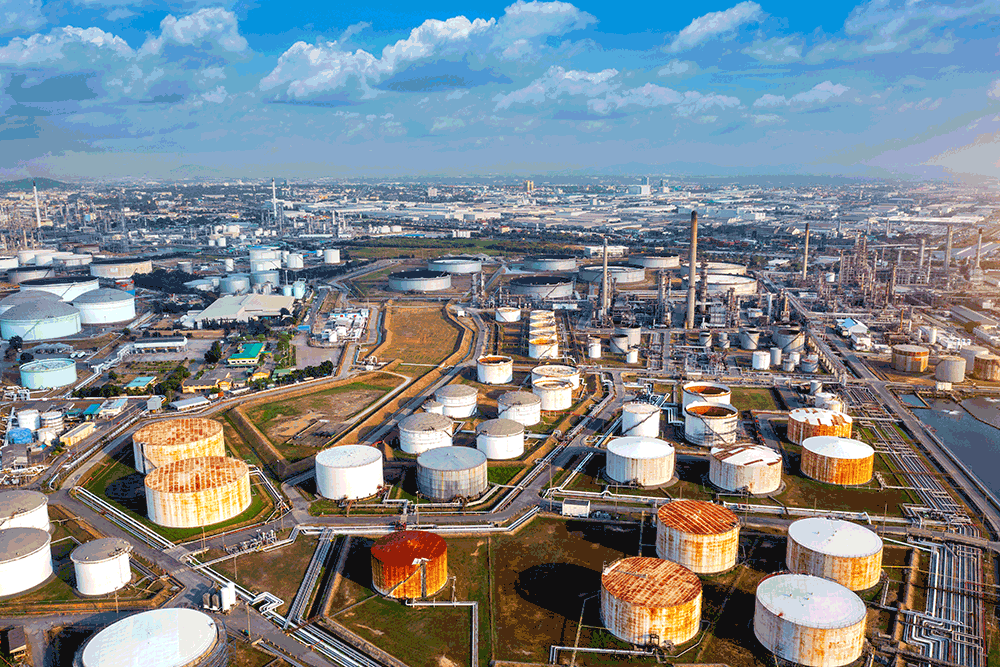

Oil and gas refineries face some of the harshest working conditions, where corrosion can cause damage to important equipment. Prolonged exposure to chemicals, high temperatures, and moisture accelerates wear and tear, leading to costly downtime and repairs.

At Metatech, we specialise in providing advanced thermal spray coatings that protect refinery equipment from corrosion, extending the lifespan of your assets, and ensuring efficient operations.

In this article, we’ll explore the range of thermal spray coatings we offer and how they provide superior protection in tough refinery environments.

ADVANCED THERMAL SPRAY COATINGS FOR REFINERIES

1. Thermal Spray Zinc Coating (TSZ)Thermal Spray Zinc (TSZ) coating is one of the most reliable solutions for protecting refinery structures in corrosion-prone areas. This coating is ideal for files, bridges, risers, and even nuclear reactors. It is widely used in refineries and chemical plants for its exceptional corrosion resistance and durability.

Key Benefits of TSZ:

- Long-Lasting Protection: TSZ provides a robust barrier that prevents rust and corrosion over long periods.

- Strong Corrosion Resistance: It offers excellent protection, even in highly corrosive environments.

- Low Thermal Load: The coating doesn’t overheat the surface, preserving the integrity of the material underneath.

2. Thermal Spray Aluminium Coating (TSA)

When dealing with moisture-driven corrosion, Thermal Spray Aluminium (TSA) coating stands out as an excellent choice. TSA is particularly effective for high-temperature components exposed to flue gases, such as reactors and offshore platforms. This coating offers exceptional resistance to atmospheric corrosion and ensures equipment longevity.

Key Benefits of TSA:

- Extended Equipment Lifespan: TSA extends the life of critical parts by 15-20 years.

- Superb Adhesion & Minimal Maintenance: The coating bonds well with surfaces and requires minimal upkeep, reducing maintenance costs.

- High Resistance to Corrosion: TSA helps in protecting equipment exposed to moisture and harsh atmospheric conditions.

We’ve successfully applied TSA in collaboration with leading companies like Shell, ExxonMobil, and ONGC to protect reactors, pipelines, and more.

3. Thermal Spray SS316L Coating

In refineries where excessive corrosion is caused by chemicals, flue gases, or high temperatures, Thermal Spray SS316L coating provides a highly effective solution. This coating is commonly applied to flare stacks, chemical storage tanks, pipelines, and water stripper columns, safeguarding against corrosion and prolonging the life of critical equipment.

Key Benefits of SS316L:

- Chemical Resistance: Protects equipment from aggressive chemicals and flue gases.

- Prevents Costly Shutdowns: By minimising corrosion, SS316L helps avoid equipment failure and unplanned outages.

4. Thermal Spray Inconel 625 Coating

Our Inconel 625 coating is designed to resist both corrosion and erosion in high-temperature environments. It is ideal for applications such as flare stacks, chimneys, and reactors, providing superior protection against the aggressive conditions found in oil and gas refineries.

Key Benefits of Inconel 625:

- Superior Resistance: Handles harsh conditions, including exposure to flue gases and high temperatures.

- Extended Equipment Lifespan: Reduces wear, extending the life of important refinery components.

Other Specialised Coatings

In addition to the coatings mentioned, we also offer specialised options customised to refinery needs:

- Phosphorous Bronze Coating

- Zn/Al (85/15) Coating

- Ball Valve Coating

- Hastelloy Coating

These coatings are designed to meet specific challenges in refinery operations, ensuring that your equipment is protected and operational.

OUR FACILITIES

At Metatech, our efforts to quality are reflected in our 25,000 sq. ft. workshop, equipped with 15-ton EOT cranes and a robotic coating facility with 6-axis robots. Our facility also includes an acoustic chamber with a dust collector and job rotator to ensure quality coating application.

OUR PARTNERS

We are proud to be trusted by major industry players such as Shell, ONGC, Indian Oil, Bharat Petroleum, Reliance Industry Limited, ExxonMobil, and many others. Our coatings are designed to extend equipment life while reducing maintenance and downtime, making us a preferred partner for refinery protection.

Contact us today at www.thermalsprayworld.com to learn more about how we can help safeguard your refinery assets.

For more details around the coatings, you can also follow our founder Bhavik Patel on LinkedIn.