Analysis of Thermal Spray Coating Market

INTRODUCTION

The thermal spray coating industry is growing steadily, with an estimated market size of USD 10.46 billion in 2023, projected to expand at a rate of 4.8% annually until 2030.

This growth can be linked to increasing demand from industries such as automotive, aerospace, medical, and energy, where thermal spray coatings play an important role in improving component durability, providing heat resistance, and protecting against corrosion.

What’s leading the Market Growth?

1. The rising use of gas turbines in sectors like aviation, shipbuilding, and power generation is a significant factor driving the thermal spray coating market.2. With the U.S. transitioning towards natural gas for power generation, the demand for gas turbines (and subsequently for coatings that protect turbine components) is on the rise.

3. Additionally, the growing need for orthopaedic implants in an ageing population, especially in the U.S., is creating demand for thermal spray coatings to ensure the durability of medical devices.

4. Environmental regulations are also encouraging the adoption of thermal spray coatings as industries move away from harmful techniques like hard chrome plating, which produces carcinogenic byproducts.

Thermal spray coatings, being more eco-friendly and compliant with environmental guidelines, are filling this gap.

Metatech: Helping industries with Advanced Thermal Spray Coating Solutions

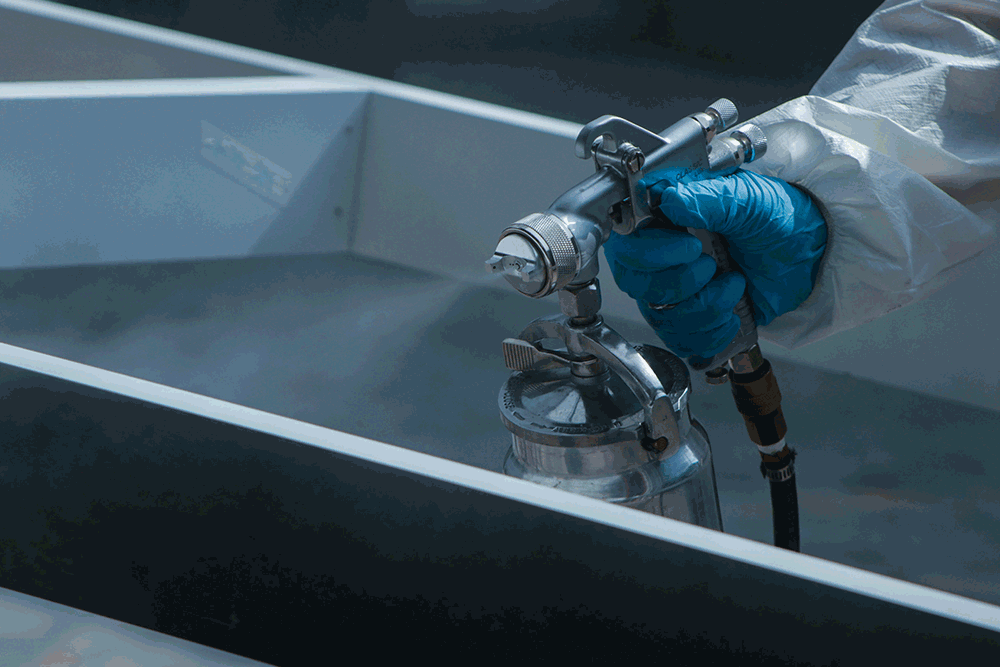

In today's industrial world, the importance of durable, efficient, and sustainable surface protection cannot be overstated.Metatech delivers thermal spray coating services, providing industries with solutions to improve the longevity and performance of their machinery and equipment.

Metatech specialises in a variety of thermal spray coating techniques customised to meet the needs of industries like steel, chemicals, power plants, and more.

One of their key offerings includes tungsten carbide coating, known for its exceptional wear resistance, ensuring the longevity of critical components like plastic extrusion screws and rot rolls.

Whether it's boiler tube coating to protect against high-temperature corrosion or tungsten carbide coating on screws for durability in extreme environments, Metatech's solutions are designed to increase equipment efficiency while reducing maintenance costs.

Conclusion

In conclusion, 2024 is shaping up to be an important year for the thermal spray coating market, with continued growth driven by innovation, environmental regulations, and increasing demand across key industries.As companies look for sustainable and efficient solutions, thermal spray coatings will play a major role in the future of industrial manufacturing.

For more details around the coatings, you can also follow our founder Bhavik Patel on LinkedIn.